Introduction

All functions, in any business or organization, are connected and interlinked to each other and are often overlapping. Some key aspects like inventory management, supply chain management, and logistics are the foundation of the business delivery function. Therefore, these functions are immensely important with respect to the smooth workings of a business.

Now, think about some retail shop, be it your favorite boutique or a big enterprise and ask yourself a couple of questions:

- Do they stock goods both online and in-store?

- Do they have the products in stock that you frequently want?

If both the answers are yes, chances are the companies have a good inventory management system.

Here, we will discuss why a proper Inventory Management system should be in place for the accurate functioning of a business. But to understand its importance, first we need to be aware about Inventory, its types, its functions and how it is controlled.

What is Inventory?

Inventory can be referred to as the accounting of items, its components, raw materials and finished goods that a company sells or utilizes in production or manufacturing of its products. Inventory is also considered to be a current asset and is referred to all stock in the various production stages.

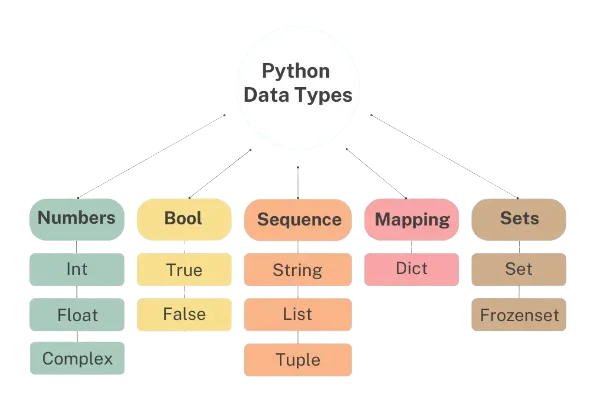

What are the different types of Inventory?

There are 12 different types of inventory that have been recognized. These include raw materials, components, work-in-progress (WIP), finished goods, packing and packaging materials, safety stock and anticipation stock, service inventory, decoupling inventory, cycle inventory, transit inventory, theoretical inventory, and excess inventory. There is another one – maintenance, repair and operations goods (MRO), but some people do not recognize MRO as a type of inventory.

What are the basic functions of inventory?

There are four main basic functions of inventory that assists in a business. These are as follows:

- To fulfill the expected demand for the products

- To protect against stock-outs

- To expedite requirements for production

- To segregate operations

What is Inventory visibility?

Order fulfillment operations through multiple channels have inventory typically spread across different places throughout the supply chain. The knowledge of what inventory one has and at what places is referred to as Inventory Visibility. To guarantee carrying out the customer orders, minimizing stockouts and reducing shipment turnaround times, the businesses need to have accurate information about the inventory.

Now, we will understand what inventory management is and its different aspects.

What Is Inventory Management?

Inventory management is a complex process, specifically for larger organizations, but the basics are fundamentally the same, regardless of the organization’s type or size. It can be referred to as the tracking of inventory from manufacturer to warehouses and from these facilities to point of sale. It is also known as the process of ordering, storing, using, and selling a company’s inventory. This includes the management of inventories from raw materials to finished products.

Inventory Management Process

Regardless of the type or size of organization, the Inventory Management Process begins when a company receives an order from a customer and continues until the order is shipped. This is the method when the company produces on demand. But otherwise, the process is initiated when the demand is predicted and then the purchase order is placed for the raw material requirement. The process also includes organizing the storage of products in the warehouses and analyzing sales trends.

How Inventory Management works?

The objective of inventory management is to understand the level of stock and its location in different warehouses. The software used for the process helps in tracking the flow of products from supplier through the production process to the customer. In the warehouse, inventory management helps in tracking receipt of stock, picking, packing and shipping.

Inventory Management Techniques and Terms

Some inventory management techniques use analysis and formulas to plan the company stock. Others rely on different methods and all these methods or procedures aim to improve accuracy. The techniques or methods used by a company depends on its needs and stock.

Here’s a guide to the different techniques and terms used that may help you understand it better.

ABC Analysis

This analysis method acts by recognizing the most and least in demand stock. It is an inventory management technique that finds out the value of inventory items depending on their importance.

Bulk Shipments

This method involves buying, storing and shipping inventory in bulk. It takes unpacked materials into account that suppliers load directly into ships or trucks.

Batch Tracking

This method groups similar inventory items for tracking expiration dates and tracing defective items.

Cross-Docking

This method eliminates warehousing of stock. This method works by unloading items directly from a supplier truck to the delivery truck.

Consignment

In consignment inventory management technique, the business doesn’t have to pay its supplier until a given product is sold. That supplier will also retain ownership of the inventory until the company sells it.

Demand Forecasting

This predictive analytics form of inventory management helps in predicting customer demand.

Dropshipping

The practice of dropshipping allows the supplier to ship items directly to the customer from its warehouse.

Economic Order Quantity (EOQ)

EOQ is a formula that shows exactly how much inventory a company should order so as to reduce holding and other costs.

Minimum Order Quantity

To keep costs low, a company that relies on minimum order quantity, will purchase minimum amounts of inventory from wholesalers per order.

FIFO and LIFO

First in, first out (FIFO) refers to the technique wherein the oldest stock is moved first. In the Last in, first out (LIFO) technique, the most recently-purchased inventory is sold first, considering that prices always rise, so it is the most expensive.

Just-In-Time Inventory (JIT)

This method is used by companies in an effort to maintain the lowest stock levels possible before a refill.

Lean Manufacturing

Companies using this method focus on removing waste or any item from the manufacturing system that does not provide value to the customer.

Materials Requirements Planning (MRP)

This system handles the planning, scheduling and contr

olling of inventory for manufacturing.

Safety Stock

Safety Stock is an inventory management norm that ensures there is always extra stock set aside to avoid a situation wherein the company can’t replenish those items.

Reorder Point Formula

This formula helps to find the minimum amount of stock a company should have before reordering. This helps the company to manage their inventory accordingly.

Six Sigma

This can be referred to as a data-based method for the removal of waste related to inventory from businesses.

Lean Six Sigma

This method combines together Six Sigma practices and lean management for the removal of waste and increased efficiency.

Why is Inventory Management important?

We can say that inventory is a company’s most important asset. It has its reasons. All the components of the supply chain link up to inventory management. Too little or too much inventory can be a cause of concern and pose a liability for the company.

Customers will be unsatisfied if there is too little inventory as and when needed. Moreover, large inventories bring with them their own share of issues – damage, theft, risk of spoilage and most importantly, the cost to store and insure it. Thus, inventory management is vital as it ensures there is an appropriate amount of stock on hand, reducing the risk of stockouts and even the risk of storing the extra.

Benefits of Inventory Management

The two major benefits of inventory management are that it makes sure the company is able to fulfill incoming orders and increases profit. It also provides the following benefits:

Helps to save money

Inventory management helps the company to understand its stock trends i.e. what amount of stock is stored at what location. This allows the company to utilize the stock better and fulfill orders pulling out stock from any storage location. This helps in reducing spoilage of stock and also reduces the cost involved with inventory.

Improves cash flow

Proper inventory management allows the company to spend money on inventory that sells, so that there is always a constant flow of cash through the business.

Provides customer satisfaction

Accurately managed inventory helps the business gain loyal customers by delivering them the items they want without waiting.

Key Features of Effective Inventory Management

The salient features of effective inventory management are as follows:

- Inventory Tracking – Knowledge of inventory movement through the supply chain

- Order Management – Tracking orders, customizing price, sending quotes and managing returns

- Transfer Management – Moving product to where it’s most valuable

- Reporting & Analytics – Evaluating patterns to forecast demand and sales

- Purchasing – Creating and managing purchase order

- Shipping Capabilities – Automating shipping to reduce delivery related errors

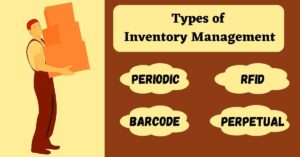

What are the four primary types of Inventory Management?

Companies must have accurate knowledge about their inventory in order to remain competitive. Without knowing what fate is awaiting them, taking decisions regarding future procurement and distribution work can be rendered impossible. The four primary types of inventory management are discussed below :-

Periodic Inventory Management

Periodic inventory management, as the name suggests, aids in evaluating stocks at specified intervals. It is a physical process that helps the company estimate the cost of goods sold.

Barcode Inventory Management

Companies use barcode inventory management systems for assigning a number to each product they sell. It helps in organizing and speeding up daily tasks while boosting efficiency and accuracy.

RFID Inventory Management

Radio Frequency Identification (RFID) is another important facet that many inventory management systems include and support. Based on RFID, the warehouse management system can increase inventory visibility, improve efficiency, and ensure the rapid self-recording of receiving and delivery.

Perpetual Inventory Management

It is another system wherein the inventory records are updated continually. This helps save money and time as repeated checks on stock levels can be avoided. The benefit of this system is that it provides up-to-date inventory level information.

Inventory Management Challenges

Having too much inventory and not being able to sell it or not having enough inventory to fulfill orders, are the primary challenges of inventory management. Another challenge is not understanding what items the company has in inventory and where they’re located. There are few other obstacles like getting accurate stock details, poor processes, constantly changing customer demands, and using warehouse space well.

How is Inventory Management different from other processes?

Inventory management, a process that controls all stock within a company is sometimes confused with related practices. Now, let’s discuss how it is different from other processes.

Inventory Management vs Inventory Control

Inventory control can be considered as a part of the overall inventory management process. It manages the movement of items within the warehouse.

Inventory Management vs Inventory Optimization

Inventory optimization can be referred to as the process of using inventory in the most efficient way so as to minimize the money spent on stock and its storage.

Inventory Management vs Order Management

Order management is referred to as the process of receiving and tracking customer orders. The software used often combines both tasks. Inventory management plays a crucial role in order management.

Inventory Management vs Supply Chain Management

Supply chain management is referred to as a process that manages supply relationships outside a company and the flow of stock into and through a company. For a properly running supply chain, inventory management is essential.

Inventory Management vs Warehouse Management

Warehouse management complements inventory management. Warehouse management refers to the organization of stock in a warehouse. The key to streamlining the warehouse operations is a meticulously laid out and practically organized facility.

Inventory Management vs Logistics

Logistics is the act of controlling

processes in a warehouse and in the refilling and delivery systems. Inventory management is an essential part of how companies manipulate their logistics. The relationship between logistics and inventory management is interdependent. Logistics need inventory management to perform their activities.

Inventory Management vs ERP

An enterprise resource planning (ERP) system is referred to as a software that helps in managing the business activities such as purchasing, accounting, compliance and supply chain operations.

ERP systems provide companies with accurate inventory data, so they have the most updated information for their inventory management plan. ERP systems help in optimizing the data so the process is successful.

How to improve Inventory Management?

There are many ways to improve the efforts of the inventory management process. One of them includes keeping accurate accounting records and taking regular physical stock counts. A system that provides the organization with real-time visibility into inventory can help stakeholders make critical business decisions. Companies should also be aware of a stock’s condition, especially if the organization is dealing with perishables.

Conclusion – The Future of Inventory Management

Empowered consumers along with enhanced technology and globalization are changing the way businesses manage inventory. Supply chain operators will use technologies that provide significant insights into how supply chain performance can be enhanced. They’ll foresee abnormalities in logistics performance and costs before they take place and have insights into where automation can deliver remarkable advantageous results

In the near future, these new and enhanced technologies will continue to transform inventory management.

Internet of Things

Inventory location and status will now be easily tracked with insight data from IoT sensors.

Artificial intelligence

Inventory monitoring will be more accurate and will reduce material waste through Intelligent and self-correcting AI.

Blockchain

Different parties will be connected through a united and unchangeable record of all transactions.

Quantum computing

Unparalleled computational power will help solve earlier unsolvable problems.

Intelligent order management

Supply chains will learn inventory visibility well with enhanced automation and demand forecasting.

Frequently Asked Questions

1. What is the main purpose of inventory management?

The main purpose of the process is to make sure that there are adequate materials or goods to fulfill demand without having to overstock.

2. What are the 5 objectives of inventory management?

The 5 main objectives of Inventory Management are as listed under:

- To keep material availability

- To keep losses and wastage to a minimum

- To maintain sufficient stock

- To enhance level of customer service

- To reduce cost value of inventories

3. What is the best way to manage inventory?

Some of the techniques and best practices to be followed for small businesses are as follows:

- Accurate forecasting

- Use the FIFO (First-in-first-out) technique

- Have the stock audited from time to time

- Stock levels should be tracked in a timely manner

- Using of cloud-based management software

4. What is the first rule of inventory management?

The first rule of Inventory Management is having adequate inventory to fulfill demand. In the past, when inventory got exhausted, companies would simply issue a backorder while they purchased or manufactured more items.

5. What are the 2 methods of inventory control?

There are two key types of inventory control systems which are mentioned below:

- Perpetual inventory system: It helps in tracking inventory in real-time

- Periodic inventory system: It is kept updated by a physical count of goods on hand at specific intervals.